College kids are thirsty and some are full of motivation and ideas. I was one of these motivated thirsty kids with an idea. Being thirsty I drank lots of stuff (much of the time cans of beer). It seemed like I was always throwing away cans of beer from me and my friends. Then I got my idea, I would keep all these cans instead of throwing them away. Then I would melt the cans into liquid form and pour this liquid aluminum into some sort of mold and make something useful. My first idea was a pair of big swords that could be used for mock sword fights and as decorative items on the wall.

Well after some research I found out that there was a couple of problems with this idea. First to get enough aluminum to complete this project I would need more cans then I could possibly store at my apartment. Second the Aluminum would not be strong enough to fight with or even hold itself together. So I changed my idea to be one small sword with rebarb and stuff inside to give it stability. Eventually it was discovered that even this was going to be too much aluminum and so instead of saving up for more cans I decided to do a test run first.

I had recently installed a kegerator and decided a custom made tap handle out of old beer cans would be a great useful object. So I got a piece of Styrofoam and carved out my mold. It was a strong mold, cool shape and had a slot built in where you could put the plastic cap from the keg to display what beer was in the keg. I stuck a metal rod in the middle of the mold with threads on it that would screw into my tap when done.

Then I burried the mold in some soft sand and left a small hole in the end to fill it from.

The theory here is that the melted aluminum is very hot and when pored onto the sand it will melt the Styrofoam and take the shape of it. The sand will hold it in place and allow it too cool and harden. The next step was melting the cans. With the help of Jon, Joel and Kentaro we created a furnace that we believed would be hot enough to melt the cans.

We dug a small deep pit, roughly 2 feet or so deep and 12 inches by 6 or 8 on the sides. We also put a small hole leading to the bottom of the pit and inserted a vacume pipe that was set to blow out air.

Then we filled the hole with charcoal. On the ground above we put down some railroad ties and across them a large metal bar with a standard cast iron dutch oven wired to it.

This allowd us to raise and lower the pot and move it on and off the fire when adding cans and whatnot. We also attached some vice grips and a pipe to the pot so we could pour the pot when it was full of aluminum.

We smashed cans so more would fit in the pot at a time then filled the pot and lit the fire.

Once the fire was going we turned on the vacume and the fire began to roar.

The fire chugged and chugged on the plentiful supply of air and fuel. We continuously added charcoal, more cans and checked on everything.

We burned through our charcoal supply in no time and had to get more and more. Eventually 9 big bags of charcoal were put in and I don’t remember how many cans.

We occasionally opened the lid and investigated the aluminum. The ink from the cans was on top and the metal in various states of liquidity was at the bottom of the pot. Everything was going really well it was just taking a while because only so many cans would fit in at a time.

Then disaster strook, we opened the pot and stirred up the mixture to add more cans and the bottom of the pot dropped out. The cast iron pot melted through and poured all our aluminum into the fire and destroyed my dutch oven.

I did some searching and found Wikipedia’s entry on cast iron. It claims that cast iron’s melting temperature is 1150 to 1200 °C. That translates to about 2000 degrees Fahrenheit. Aluminum melts at 1221 degrees Fahrenheit so our fire was probably more then twice as hot as it needed to be. So the fire was too hot and it destroyed my ideas for using up my old beer cans for something useful. I think we could try this again sometime and use a ceramic or some stronger metal for the pot but no plans are set for such a project at this time.

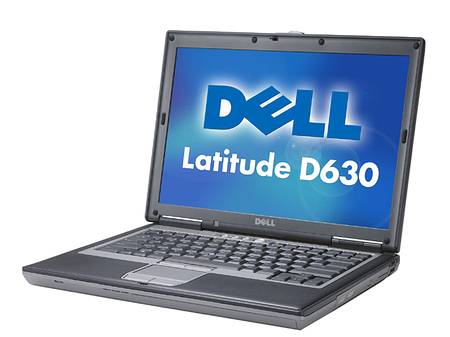

Early morning calls from the boss could be cause for alarm but this time he had some good news. They are going to replace my out of warranty slow laptop for a new shiny one.

Early morning calls from the boss could be cause for alarm but this time he had some good news. They are going to replace my out of warranty slow laptop for a new shiny one.

– 27

– 27

– new house

– new house